There are cases when the user of a turbocompressor may consider whether the machine can be modernized, or revamped, to be applied for the gas compression at different performance parameters or for the compression of an entirely different gas. Such a modernization, when feasible, can offer substantial benefits to the user. First, smaller expenditures have to be met as compared with the purchase and installation of a new compressor. Second, and this relates to the process turbocompressors in particular, the problem encountered by the user can be solved in a much shorter time.

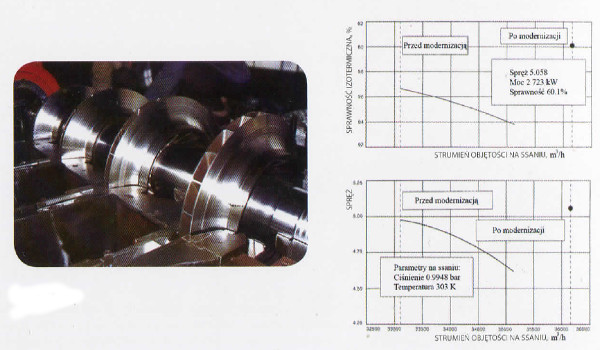

TURBOSERVICE has an extensive and rich experience in the respective "turn-key" modernizations of various turbocompressors that were manufactured years ago and of which the original manufacturers no longer exist in some cases. The modernizations are based on the redesign of the compressor's internal ("flow") parts whereby the compressor casing, the connecting pipings and most of the auxiliaries remain unchanged. Modern materials and manufacturing technologies are used for the production of the new machine components. An example of a new, revamped air turbocompressor rotor is shown in the illustrations below.

By the implementation of the modern control and monitoring systems the machines that are already in operation can be modernized also with a view to their better and more reliable interaction with other components of the respective process installation. Sometimes this is the machine failure that, because of the necessary repair, offers the opportunity to implement the newest materials, manufacturing techniques, etc..

On request, TURBOSERVICE can quickly assess the chance for modernization of the customer machine and provide the answer whether it can be applied for the required service. This procedure refers to the turbocompressors still being in normal service as well as those that have been no longer used.