In 1995, TURBOSERVICE received an order from Petrochemia PLOCK for revamp of the 2.7 MW air compressor.

The following work schedule was applied :

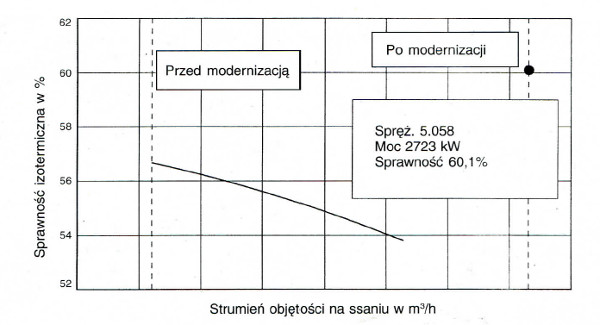

- Site test of the compressor. This provided data of the actual performance of the compressor and enabled of the guarantee point to be given by Turboservice.

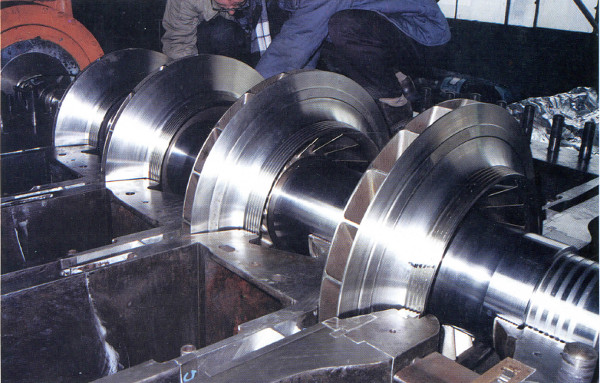

- Geometry of the rotor and stationary components was measured.

- Complete technical documentation of the new and vaned diffusers was prepared. Out of 4 impellers, two were designed with 3-D blades having higher blade angle values and larger widths. New diffusers were also designed to match the new impeller blade angles. New version of the thrust bearing disc was designed, to facilitate an easy dismantling from the shaft.

- Original aluminum diffusers were replaced by milled stainless steel diffusers to increase corrosion and erosion resistance. The compressor rotor was manufactured in line with API 617 standard and the whole production process was kept within ISO 9001 quality standard.

- Precise fitting of the new diffusers into the compressor casing and assembly of the revamped rotor was supervised by TURBOSERVICE.

- The contracted guarantee point was then measured during the performance test. It was confirmed that the compressor yielded 16% increase in capacity accompanied by 4 pcts increase in efficiency as compared with its performance prior to the revamp.